INTRODUCE :

SR1568 Solar Hot Water Controller

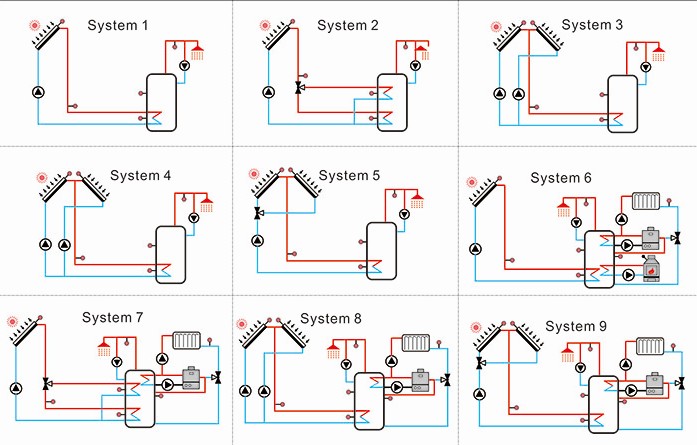

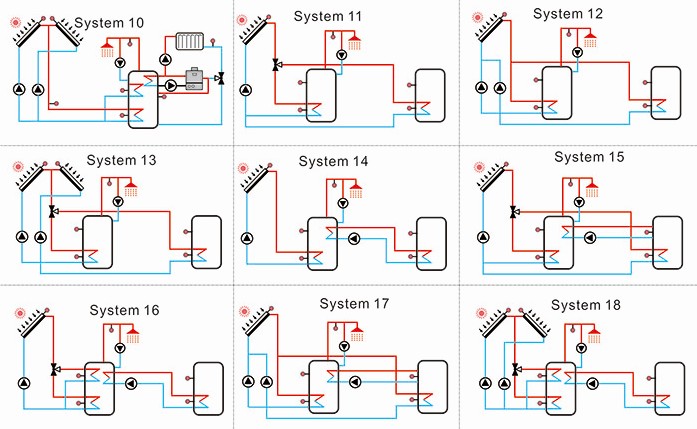

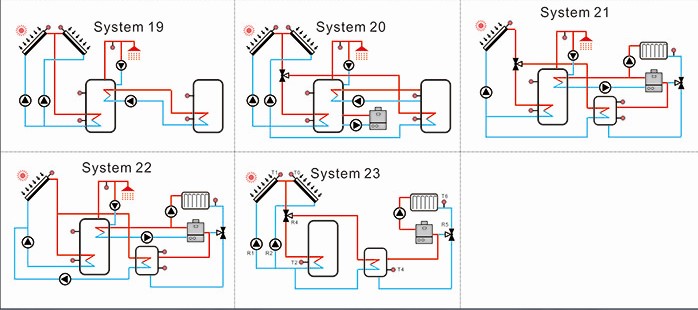

23systems can be programmer

RS485 communication port

Combine with wifi module can internet access

Conventional/HE pump both available on

Support firmware update by SD card or internet

Free offer remote monitor management server.

For below solar hot water system :

Split type high pressure system

Split type Low / Non pressure system + Assistant tank with float ball

Controller introduction

TFT colorful screen display

6 * relay outputs

1 * low voltage relay output

7 * sensor inputs

1 * Grundfos Direct Sensor TM (VFS) simulation input

1 * Grundfos Direct Sensor TM (RPS) simulation input

3 * Variable frequency PWM outputs for the speed

control of the high efficiency pump

Data saved on the TF card (Micro SD)

485 communication port

23 systems for choose

APPLICATIONS CAPACITY

Max.number of collectors:2

Max.number of storage tanks:2

Max.number of relays:7

Max.number of sensors:8

Max.number of visualization application system:23

Signal port for HE pump:IPWM1,IPWM2,IPWM3

Communication port:1*rs485

RPS:1*Grundfos pressure sensor

VFS:1*Grundfos flowmeter sensor

Main technical data

Size of Controller: 208mm x158mm x43mm

Power supply: AC100-240V50-60Hz. .

Power consumption: < 2.5W

Rated impulse voltage: 2.5KV

Data interface: TF(micro SD)

485 current supply: 60mA

Housing: Plastic ABS

Protection type: IP41

Protection class: 1

Degree of pollution: 2

Mounting: Wall mounting

Indication/Display: System Monitoring Display for visualization of the system TFT colorful and background illumination.

Operation: 5 push buttons at the front cover.

Accuracy of temperature measuring: ± 0.1oC

Range of collector temperature measuring: -10oC ~220oC

Range of tank temperature measuring: 0oC ~110oC

Suitable power of pump: 6 pump possible to be connected

Suitable power of HK (backup heating): 1pc *220W .

Inputs: 8 sensors

2pcs*Pt1000 sensor (≤500oC) for collector (silicon cable≤280oC)

6pcs*NTC10K B3950 sensor (≤ 135oC) for tank (PVC cable ≤105oC)

Outputs: 7 relays for circulation pump and backup heating

3*Electronmagnetic relay Max.current 1A

3*Semiconductor relay Max.current 1A

1*Potential-free extra-low voltage relay(on/off signal)

3*PWM variable frequency output(switchable 0-10v)

Ambient temperature: -10oC ~ 50oC.

Water proof grade: IP41

Delivery list

1 * SR1568 controller

1 * accessory bag

1 * user manual

2 * screen and expansion

2 * PT1000 temperature sensor (φ6*50mm,cable length 1.5meter)

5 * NTC10K temperature sensor (φ6*50mm,cable length 3meter)

1 * clamp bag

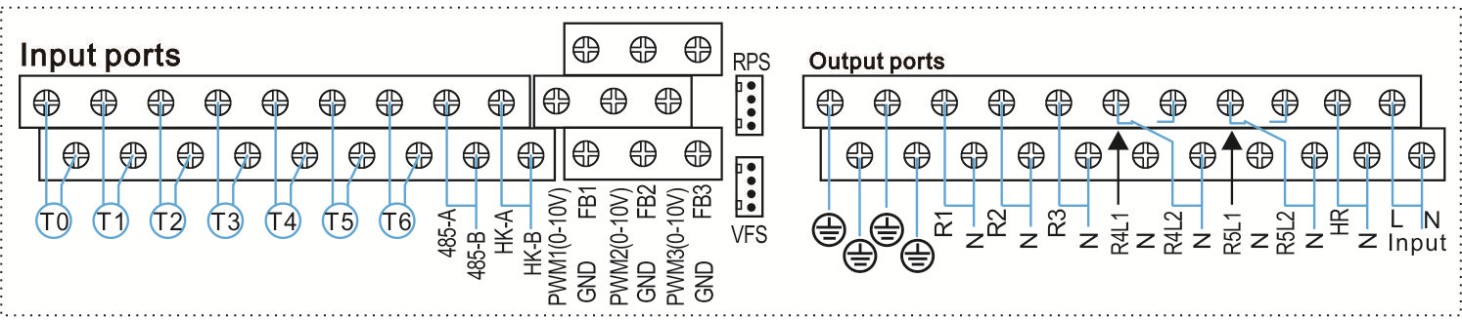

Terminal connection

T0~T1: PT1000 temperature sensor, for measuring the temperature of collector and thermal energy calculation.

T2~T6: NTC10K, B=3950 temperature sensor, for measuring temperature of tank and pipe.

Communication port 485: ELA485, for remote control communication

HK-A, HK-B:Dry connection on/off signal ports, (HK and HR simultaneously open or close for boiler heating control)

PWM1, PWM2, PWM3: Signal ports for high efficiency pump, detailed connection see below

RPS: For Grundfos pressure sensor

VFS: For Grundfos flowmeter sensor

Input Ports L N: for power connection, L: live wire, N: zero wire, PE: protective wire

Output R1: Semiconductor relays (SCR), designed for pump speed control, Max. Current: 1A

Output R2: Semiconductor relays (SCR), designed for pump speed control, Max. Current: 1A

Output R3: Semiconductor relays (SCR), designed for pump speed control, Max. Current: 1A

Output R4: Electromagnetic relays, designed for control of pump or 3-ways electromagnetic valve, Max. Current: 1A

Output R5: Electromagnetic relays, designed for control of pump or 3-ways electromagnetic valve, Max. Current: 1A

Output HR: Electromagnetic relays, designed for control of back-up heating device, Max. Current: 1A

Main functions:

DATE---Date setting

Light---Display lightness adjustable

Timed heat---backup heating

Circle---Hot water circulation

Sys—Application programmer

LOAD---Setup Loading tank1

LOAD2--- Setup Loading tank2

COL---Collector1

COL2---Collector2

PUMP---Pump control mode

LLOGI---Tank loading logic

COOL---Cooling function

HEATX---Thermal energy transfer between tanks.

RPH---Preheat heating return function

AUX---Auxiliary function

MAN---Manual mode

BLPR---Blocking protection function

OTDIS---Thermal disinfection function

OPARR---Parallel relay function

OHQM---Thermal energy measurement

GFDS---Registration of Grundfos sensor

Press---Press monitoring

UNIT---C-F unit switch

OSDS---SD card

REST---reset

PASS--- password set

Firmware update

Holiday function

Screen Protection

Trouble Protection

Trouble Checking